OOPS! I missed a couple steps starting way back on page 99. The bottom of the galley flat and the insides of the quarter panels should have been epoxied then before the bottom was installed. It's going to be a bit harder to do it now but not impossible. The biggest challenge will be making sure I seal the areas I can't see, behind the reinforcing bars and the backside of the bulkhead.

Well that's better. The inside of the footwell is all sealed up now and I'm very sure I got the areas I couldn't see. If not, I can't really see how any water will get back there and even if it does it will flow off onto sealed areas right away. If wood does not stay wet it doesn't rot.

The bulkhead will not be covered up by headliner so I tried to be extra careful with its coating--even tipped it off with a foam brush, but it will still have to be sanded. At least there shouldn't be any runs or sags. It's a pretty piece of wood and it is where all the electrical controls, stereo, and so on will be mounted.

This is inside the front of the shell, just forward of the ventilation bezel. All of this will be covered by headliner, so one coat to seal it is plenty, no more sanding here either!

It's getting colder so I have put a small electric heater inside, and you can see my digital thermometer sitting on the shelf bottom. I like that it records the high and low temps for the previous 24 hours. As you can see I've put plastic sheeting over the doorways to help hold in the heat. I'll be checking the temp from time to time and adjusting the thermostat on the heater to try to keep it around 70 or so in there.

I used leftover epoxy to put the first coat on the insides of the doors. They will be exposed to rain from time-to-time so I'll be adding at least one more coat.

This will take you through my build of a Chesapeake Light Craft Teardrop Camping trailer. Maybe it's not a boat, but it is definitely a craft. (Picture "borrowed" from CLC website)

Sunday, November 27, 2016

Sunday, November 20, 2016

Beginning Work on Doors

First, the cut lines for the windows are marked. To get the curves right on the corners, I used the pre-cut acrylic windows as a guide.

The windows are different for each side, so after careful comparisons, I labeled both the window and door. Starboard side is shown.

The window openings have been cut out on each door. Much careful sanding followed to get the sides as straight and the curves as "perfect" as possible. Also, I made sure the windows fit easily into the openings. The window goes just inside the opening and the edges of the plywood will be visible, so I did them as well as I possibly could. This will also hold true for the doors and hatches and their respective openings. The "sill" (to which the window will be mounted) has been fitted to the window opening and glued in place. It is especially important to clean up squeezed out glue on the face of the sill. Once it has hardened, it becomes extremely difficult to remove and it has to be cleaned off for the window to fit properly.

NOTE TO BUILDERS: If you haven't already done so, now is the time to use rat-tail and small flat files to clean any epoxy and fiberglass out of the hinge-mounting holes on the door. Do this before adding the stiffeners in the next step. The stiffeners cover part of the bottom hole and make it much more difficult to clean it out. Also make sure any squeezed-out epoxy from the stiffeners is cleaned out of the hinge-mounting holes before it starts to harden.

The sills have cured and now the door stiffeners are sanded and glued on.

Stiffeners are installed on both doors and they are inside the house now for curing. Later on, work will continue on the doors--coating the inside with epoxy, installing the windows, adding hardware and hinges, and several other details. For now, it's back to sanding the interior of the camper shell.

Cabin Shelf Continued

Because the shelf did not quite reach the shell, I installed cleats on each side to attach it to. When the camper is turned rightside-up, I'll fill in the gaps with thickened epoxy, along with the fillets.

And here is the shelf installed. Looks like I didn't get a picture, but I added a nice fillet all along the shelf bottom and onto the cleats. Again, fillets will be added to the top side when the camper is turned over.

And here is the shelf installed. Looks like I didn't get a picture, but I added a nice fillet all along the shelf bottom and onto the cleats. Again, fillets will be added to the top side when the camper is turned over.

Monday, November 14, 2016

Cabin Shelf

I've jumped ahead a few pages to install the cabin shelf. The reason for this is that a fillet is to be run on the bottom of the shelf and that is much easier to do when the shell is upside down.

Before starting on the shelf though, I took the opportunity to round off the corner where the bulkhead meets the galley floor. That's a spot where I'm sure to be hitting my knees (remember the shell is still upside down). On the bulkhead you can see one of the slots that tabs on the shelf will be inserted into. Here are some shots of a stop or rail (called a "fiddle" in nautical terms) that is being glued to the shelf.

Be sure to round the rear corners of the shelf to clear the fillets on the bulkhead joints. I did this with a hand-sanding block. A power sander would be likely to take off too much wood very quickly.

The shelf has received two coats of epoxy, about 2 hours apart. Tomorrow I'll coat the bottom.

I went back to sanding the bulkhead and had a bit of an accident (didn't get any pictures). I was sitting inside the shell to do the sanding and it turns out it is a bit front-heavy. When I leaned back the whole thing fell forward off the furniture dolly and hit the garage floor. I checked and couldn't find any damage--epoxy is pretty tough.

The same thing would have happened if I had put it on foam blocks as recommended in the book, and in fact it would have fallen farther. At any rate I have laid a furniture blanket on the floor in case this happens again. I may add some weight at the back also to balance it better.

Saturday, November 12, 2016

Continuing Fiberglassing of Bottom and Inside Vent Bezel

Here's the bottom all sanded and ready for fiberglass.

Fiberglass laid on. Future builders and those getting started take note:

CLC doesn't provide any extra cloth. I always cut it a bit long and trim it, and as you can see I ran out before the bottom was covered. Even though I had some left over from previous projects that I used here and there, e.g., the three squares for the vent bezel, I still didn't have enough! I'm glad I still have some extra to patch in that missing area with. Anyway, looks like you'll need to be extra careful and always measure out just enough. Hold on to any you cut away for possible future needs. I added the extra here at the front, so that the overlap is on the bottom, not on the transom and quarter panels. I only plan to sand the bottom enough for paint to stick--not going to worry about hiding joints like this one. At this point, the bottom has received two coats of epoxy. The manual doesn't call for a second coat, but I think it's a good idea, to help avoid sanding into the fiberglass cloth. I add the second coat when the first coat has started to cure but is still a bit tacky. You can probably tell from this photo that I didn't do that great a job on the corners around the end of the butt block. It's a pretty big job and I couldn't spend a lot of time messing with those areas before the epoxy started to kick so I had to move on.

So I sanded the excess off and patched those areas. I found that I was able to make a small patch of cloth conform nicely to the shape. More rounding of the butt block corner might have solved this.

This is after the second coat of epoxy. I'm doing the same patching on the corners. Most of them were OK, but I decided those corners might take a lot of abuse, so a little reinforcement won't hurt. I'll be doing the same thing on the front end of the shell.

Here's the inside of the vent bezel all sanded and ready for fiberglass. It's still damp with alcohol at this point--that dried in a few seconds.

The cloth has been applied,

and two coats of epoxy. You may remember that the edges of the bezel were just barely touching the shell, but I believe after the fillets and all the fiberglassing it is going to be plenty strong.

Fiberglass laid on. Future builders and those getting started take note:

CLC doesn't provide any extra cloth. I always cut it a bit long and trim it, and as you can see I ran out before the bottom was covered. Even though I had some left over from previous projects that I used here and there, e.g., the three squares for the vent bezel, I still didn't have enough! I'm glad I still have some extra to patch in that missing area with. Anyway, looks like you'll need to be extra careful and always measure out just enough. Hold on to any you cut away for possible future needs. I added the extra here at the front, so that the overlap is on the bottom, not on the transom and quarter panels. I only plan to sand the bottom enough for paint to stick--not going to worry about hiding joints like this one. At this point, the bottom has received two coats of epoxy. The manual doesn't call for a second coat, but I think it's a good idea, to help avoid sanding into the fiberglass cloth. I add the second coat when the first coat has started to cure but is still a bit tacky. You can probably tell from this photo that I didn't do that great a job on the corners around the end of the butt block. It's a pretty big job and I couldn't spend a lot of time messing with those areas before the epoxy started to kick so I had to move on.

So I sanded the excess off and patched those areas. I found that I was able to make a small patch of cloth conform nicely to the shape. More rounding of the butt block corner might have solved this.

This is after the second coat of epoxy. I'm doing the same patching on the corners. Most of them were OK, but I decided those corners might take a lot of abuse, so a little reinforcement won't hurt. I'll be doing the same thing on the front end of the shell.

Here's the inside of the vent bezel all sanded and ready for fiberglass. It's still damp with alcohol at this point--that dried in a few seconds.

The cloth has been applied,

and two coats of epoxy. You may remember that the edges of the bezel were just barely touching the shell, but I believe after the fillets and all the fiberglassing it is going to be plenty strong.

Thursday, November 10, 2016

Preparing to Fiberglass the Bottom

The manual says to turn the shell upside-down and set the bezel on some foam blocks. Since I have to move it around by myself I decided to put it on a furniture dolly instead.

The rear of the camper is supported by a sawhorse. The homemade sawhorse I had was too short so I went down and bought one that has adjustable legs. At its shortest setting, 32", it is just the right height.

The first step is to sand a roundover all around the perimeter of the bottom, because the fiberglass will roll over onto the sides about an inch or so. There is a problem at each end of the butt block, though. This is the rear end where I decided to cut off the tabs (the right one is already removed) and fill in the whole area:

Here it is filled in and curing. This will give the cloth a place to "flow" smoothly down onto the transom. I'm not sure what's going to happen at the sides of the butt block--I hope I can make the cloth conform, otherwise will have to cut some darts.

And here is the rear end sanded. The front end got the same treatment.

There is more filling and sanding yet to do at the ends and all around the sides, then comes the fiberglass treatment.

The rear of the camper is supported by a sawhorse. The homemade sawhorse I had was too short so I went down and bought one that has adjustable legs. At its shortest setting, 32", it is just the right height.

The first step is to sand a roundover all around the perimeter of the bottom, because the fiberglass will roll over onto the sides about an inch or so. There is a problem at each end of the butt block, though. This is the rear end where I decided to cut off the tabs (the right one is already removed) and fill in the whole area:

Here it is filled in and curing. This will give the cloth a place to "flow" smoothly down onto the transom. I'm not sure what's going to happen at the sides of the butt block--I hope I can make the cloth conform, otherwise will have to cut some darts.

And here is the rear end sanded. The front end got the same treatment.

There is more filling and sanding yet to do at the ends and all around the sides, then comes the fiberglass treatment.

Saturday, November 5, 2016

Installing the Transom

Here is the transom from the outside, stitched to the quarter panel and galley floor. It was not quite touching the camper floor so I added some temporary screws to hold it while it is being glued (no picture).

What follows is one of the worst jobs on the project: crawling into that little cave and filleting and taping/epoxying all four joints on the transom.

The hardest part was the top joint, just below the galley floor. You can't tell from this angle but the tape has to bend back toward itself. I was expecting to do a really horrible job because it is so hard to get at, but it came out looking pretty good. Much of the transom itself is painted with epoxy because of all the spills. That was to be expected. Later the entire inside of the camper will be coated with epoxy.

And this shows the top, one side, and bottom joints all filleted and taped/epoxied. These joints need to be strong, and I'm not worried.

The hardest part was the top joint, just below the galley floor. You can't tell from this angle but the tape has to bend back toward itself. I was expecting to do a really horrible job because it is so hard to get at, but it came out looking pretty good. Much of the transom itself is painted with epoxy because of all the spills. That was to be expected. Later the entire inside of the camper will be coated with epoxy.

And this shows the top, one side, and bottom joints all filleted and taped/epoxied. These joints need to be strong, and I'm not worried.

Building and Installing Roof Ventilation Bezel

Because the top of the camper is curved, a bezel is added to create a flat area for mounting a ventilation fan. This shows the bezel upside-down after assembling.

The joints are filleted followed by the addition of fiberglass cloth and epoxy.

And here is where I ran into problems. The cutout hole is almost too big for the bezel!

From beneath, you can see that I did not cut it larger than the precut slots. In fact you can see the parts of the slots that are left after I ran the saw down the middle of each of them. My advice to future builders is to cut the opening a little too small--just inside the slots or even a little smaller. It is much easier to widen the opening later to fit the bezel. But that may not be necessary as the mounting for the ventilator will probably cover the edge up anyway. The manual does not call for stitching wires, but holes were pre-drilled so I used them. The bezel just barely covered the opening in some parts, but with the wires I was able to keep it in the right place while I glued and filleted. Rather than apply thickened epoxy to the bezel first, I stitched it loosely, applied the epoxy, and then tightened the wires. With the fillets and fiberglass cloth on both sides it should be plenty strong. (I hope so because the bezel has to support the camper later when I turn it back upside-down for more work.)

Here's the bezel after I applied the thickened epoxy. I cleaned it up pretty well after this, but didn't shoot a picture.

Oh wait, yes I did. After it cured I removed the wires and worked on the outside.

And here it is filleted and fiberglassed. A hole will be cut in the flat top to accommodate a ventilation system.

The joints are filleted followed by the addition of fiberglass cloth and epoxy.

And here is where I ran into problems. The cutout hole is almost too big for the bezel!

From beneath, you can see that I did not cut it larger than the precut slots. In fact you can see the parts of the slots that are left after I ran the saw down the middle of each of them. My advice to future builders is to cut the opening a little too small--just inside the slots or even a little smaller. It is much easier to widen the opening later to fit the bezel. But that may not be necessary as the mounting for the ventilator will probably cover the edge up anyway. The manual does not call for stitching wires, but holes were pre-drilled so I used them. The bezel just barely covered the opening in some parts, but with the wires I was able to keep it in the right place while I glued and filleted. Rather than apply thickened epoxy to the bezel first, I stitched it loosely, applied the epoxy, and then tightened the wires. With the fillets and fiberglass cloth on both sides it should be plenty strong. (I hope so because the bezel has to support the camper later when I turn it back upside-down for more work.)

Here's the bezel after I applied the thickened epoxy. I cleaned it up pretty well after this, but didn't shoot a picture.

Oh wait, yes I did. After it cured I removed the wires and worked on the outside.

And here it is filleted and fiberglassed. A hole will be cut in the flat top to accommodate a ventilation system.

Wednesday, November 2, 2016

Installing Part of the Galley Hatch Gutter

There will be a gutter that goes all the way around the galley hatch so that rainwater can drain out. It starts as a flat piece and will have gaskets and so on added later to guide the water out.

Earlier I glued a gutter "riser" to the back of the galley. The lower part of the gutter will be glued to that. A slot for the riser was pre-cut, so about all I had to do was glue it in place.

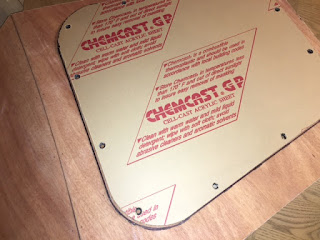

The two pieces that will become the flat part of the gutter have had fiberglass cloth and epoxy applied because they will probably take a lot of abuse.

The top piece has been slotted into the bulkhead. I am going to send this picture to CLC because the part does not fit very well. There is a large gap between the gutter part and the galley wall. I had hoped it would show up better, but the part does not even reach the end of the pre-cut slot. I will have to put tape under the open area and fill it with thickened epoxy.

The second, lower piece has been added. At the right is part of the lower piece that is sitting on top of the riser I added before.

I've started a fillet all around the gutter. At the upper right corner you can just barely see where I filled in the gap, and to the right some of the blue masking tape I used to hold the fillet material in place. The gap continues along most of both sides of the upper piece.

A fillet has to go in under that lower piece--this was taken after I did what I could. The piece was also a bit long, and though I thought I had shaved it down enough, it turned out it was still popping up a bit in places, hence the clamps. I had the brilliant (so I thought) idea of putting plastic all over the galley floor and using it as a table for my tools and epoxy. That worked well until I got to the bottom piece. You have to practically stand on your head to see under there and the tool I had was too wide to work very well. I was using the "pastry bag" method and it was nearly impossible to get the spout up where I needed it. Then I was worried about getting my hair in the epoxy on the plastic--and my glasses kept falling off. So I gave up after managing to get enough epoxy between the gutter piece and the riser to hold it in place. When that cures enough I'll put in the fillet. This time the plastic, etc. won't be in the way and I'll use a caulking tube to get the epoxy where I need it. I'll have to find or fashion a smaller filleting tool. There'll be more filleting to do anyway because I'll have to do the parts on the upper sides that are covered with masking tape for now.

Subscribe to:

Posts (Atom)